Euro-SiBRAM’2002 Prague, June 24 to 26, 2002, Czech Republic

Professor Ing. Ján Hudák, PhD.

Technical University Košice, Slovak Republic

Initiation and propagation of cracks caused by variable repeated load-effects characterize the fatigue process. The fatigue process leads to progressive failure and total diminution of the service life of the loaded components of structures. Decisive factors, which determine this process are loading history and corresponding load effects history, geometrical form of structure, configuration of details, residual stresses due to rolling and/or welding etc., and eventually defects and stress concentrations. The primary influence on the fatigue damage and failure, considering the mentioned effects and factors have, first of all, the load effects history, stress concentrations and residual stresses.

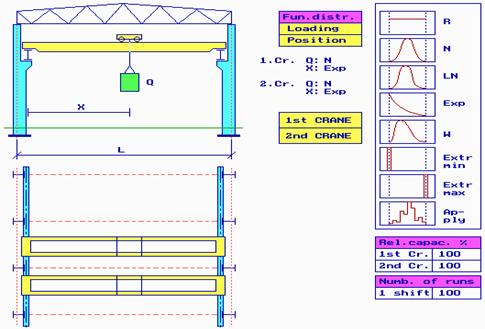

In the aspect of the solution of problem fatigue loading

and stress using probabilistic approach is necessary to give

attention to the analysis of loading and of the response of the

structure to the loading. The result of this analysis is

determination of the response spectrum, which was created by

statistically modeling the pay-load Q together with the position

of the crab

![]() within

the span of the crane

within

the span of the crane

![]() ,

with limiting lengths in the ended parts

,

with limiting lengths in the ended parts

![]() .

For dispersion variance of intensity of loading in the investigated

range and density character of probabilistic incidence is represented

by histograms (see Figure 1). We can proceed by the same method in

order to determine the crab position histogram on the crane

bridge

.

For dispersion variance of intensity of loading in the investigated

range and density character of probabilistic incidence is represented

by histograms (see Figure 1). We can proceed by the same method in

order to determine the crab position histogram on the crane

bridge![]() .

From this two quantities, which characterize magnitude of load and

its position by using of transformation model of simple beam are

determined its support reactions

.

From this two quantities, which characterize magnitude of load and

its position by using of transformation model of simple beam are

determined its support reactions

![]() for

random chosen quantities from loading spectrum

for

random chosen quantities from loading spectrum

![]() and

crab position

and

crab position

![]() .

By these supporting reactions are determined components of wheel

loading spectrum of crane

.

By these supporting reactions are determined components of wheel

loading spectrum of crane![]() ,

which by this way concisely can characterize the response of the

structure to the crane-load history.

,

which by this way concisely can characterize the response of the

structure to the crane-load history.

The value, which enters the reliability condition, is loading

effect as the result of interaction of loading and transformation

model of structure. Transformation model of structure is suitable to

elect in the form of influence line of static quantity, which is

investigated. The time diagram of loading effect for determined

period of working shift, eventually for time of one year, we obtain

by moving on the influence line of system of loading, which is

introduced by chosen wheel loading

![]() from

the loading spectrum.

from

the loading spectrum.

2. Modeling of loading

For

demonstration of introduced problem we will contemplate the crane way

girder in industrial hall of 30 m span and span of columns 6 m. In

the hall are working two cranes with carrying capacity 50

![]() and

32

and

32

![]() ,

width supposing 100 crossing per working shift. The aim of task is to

determine probability failure of steel girder

,

width supposing 100 crossing per working shift. The aim of task is to

determine probability failure of steel girder

![]() from

the point of view of fatigue loading caused by normal stress in the

lower part of girder in the middle of its spoon.

from

the point of view of fatigue loading caused by normal stress in the

lower part of girder in the middle of its spoon.

Geometrical dimensions of welded steel girder with high

1050

![]() made

from steel S235 were determined by preliminary analysis.

made

from steel S235 were determined by preliminary analysis.

At preparation of introduced characteristics of tracing

values of loading we use known nominal value of carrying capacity of

loading

![]() .

Dispersion variance of this value by using statistical analysis is

possible to consider according to loading coefficients

.

Dispersion variance of this value by using statistical analysis is

possible to consider according to loading coefficients

![]() in

range

in

range

![]() and

also

and

also

![]() .

Ended values of crab-crane position are determined by value

.

Ended values of crab-crane position are determined by value

![]() distance

especially by value

distance

especially by value

![]() and

and

![]() ,

where

,

where

![]() is

spoon of crane bridge. There are vectors

is

spoon of crane bridge. There are vectors

![]() and

and

![]() which

are generated by application of histograms, which are similar to

statistically distribution for range of minimally and maximally

values. After this preparation is possible to find necessary elements

of introduced vectors.

which

are generated by application of histograms, which are similar to

statistically distribution for range of minimally and maximally

values. After this preparation is possible to find necessary elements

of introduced vectors.

Fig.

1 Selection of histograms similar to statistically

distribution for loading

![]() and

crab-position

and

crab-position

![]()

For optional number from file![]() will

will

![]() -

element of loading vector

-

element of loading vector

![]() and

similarly for

and

similarly for

![]() will

will

![]() -element

of loading positions vector

-element

of loading positions vector

![]() .

There

.

There

![]() -

element wheel loading vector

-

element wheel loading vector

![]() can

be expressed from formula for the reaction of simple beam

can

be expressed from formula for the reaction of simple beam

![]() ,

,

![]() =

1, 2, …

=

1, 2, …

![]() (1)

(1)

Where

![]() is

weight of crane crab,

is

weight of crane crab,

![]() -

weight of crane bridge.

-

weight of crane bridge.

The wheel-loading vector will be step by step calculated

for

![]() ,

and its form is possible to express as

,

and its form is possible to express as

![]() .

.

2. Modeling of loading effects

The time course of loading effects in the tracing point of crane girder structure is possible to determine by statically transformation model using influence line. The file of quantities for course bending moment diagram can be expressed by discrete values

![]() ,

,

![]() =

1, 2, …

=

1, 2, …

![]() (2)

(2)

Where

![]() is

actual value of loading from wheel of crane,

is

actual value of loading from wheel of crane,

|

|

|

||

![]() -

Ordinate of influence line of bending moment on the crane way girder.

-

Ordinate of influence line of bending moment on the crane way girder.

Fig. 2 Vectors of values of loading

![]() ,

crab position

,

crab position

![]() and

wheel loading

and

wheel loading

![]()

As is next expressed for given geometry of girder and random choose value of wheel loading from created loading spectrum the time diagram of bending moments is determine in elected point of crane way girder. In next step are identified local extremes of bending moments and for these bending moments and designed cross section of crane way girder adequate values of normal stress are calculated.

File of values of determined stress is characterize time course of loading effects for one crossing of two cranes.

|

|

|

|

|

|

|

||

Fig. 3 Bending moments course on the crane way girder at one crossing of cranes with nominally values of loading

|

|

|

|

|||

a) Reservoir method b) Rain Flow method

Fig. 4 Stress range spectrum for one crane crossing

|

|

Fig. 5 Stress range spectrum for one working shift

|

|

|

|

Fig. 6 Stress range spectrum for one working year

Discrete values of normal stress are determined from discrete values of bending moments in single peaks of moment’s line

![]() ,

,

![]() =

1, 2, …

=

1, 2, …

![]() (3)

(3)

Where

![]() is

extreme magnitude in

is

extreme magnitude in

![]() -

peak of bending moment line,

-

peak of bending moment line,

![]() -

Inertia moment of cross section of crane way girder to central axis

-

Inertia moment of cross section of crane way girder to central axis

![]() ,

,

![]() -

Coordinate of investigated point on the girder from center of

gravity,

-

Coordinate of investigated point on the girder from center of

gravity,

![]() -

Number of extremes in tracing diagram of bending moments.

-

Number of extremes in tracing diagram of bending moments.

The introduced process is repeated for given number of crane crossings per working shift. This time course of loading effects in elected point of girder has stochastic characters and it is necessary made of retransform on the equivalents stress range spectrum. The necessary transformation is made using classifying method Reservoir.

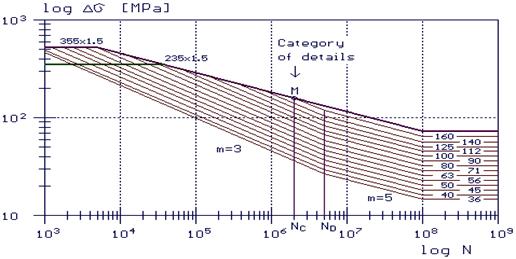

3. Fatigue damage

The fatigue strength at variable repeating loading changes in dependence on number cycles and on configuration of detail. This strength is determined from experimental results in form S-N curve. Code STN 731401 “Design of steel structures” applies three linear curves for normal stress range. The equation of fatigue strength curve is given in form

![]() (4)

(4)

Where

![]() is

fatigue strength,

is

fatigue strength,

![]() -

Number of cycles to failure,

-

Number of cycles to failure,

![]() -

Constant, which expresses inclination of fatigue strength curve,

-

Constant, which expresses inclination of fatigue strength curve,

![]() -

Constant by table 28 in STN 73 1401.

-

Constant by table 28 in STN 73 1401.

Fig. 7 S-N curves for normal stress range by STN 73 1401

4. Accumulation of fatigue damage

We will apply cumulative hypothesis of Palmgren-Miner. This

hypothesis is based on the assumption that

every individual change of stress

range

![]() ,

which

,

which

![]() multiple

repeating would cause break, will cause damage

multiple

repeating would cause break, will cause damage

![]() ([8]).

Total damage is expressed in form

([8]).

Total damage is expressed in form

![]() (5)

(5)

Where

![]() is

number of cycles in spectrum for stress range level

is

number of cycles in spectrum for stress range level

![]() ,

,

![]() -

Number of cycles to damage for stress range level

-

Number of cycles to damage for stress range level

![]() .

.

Table 1 – numerical data of value of spectra from by fig. 6

|

Stress level |

|

Spectrum of one year

|

S-N curve

|

S-N curve

|

|

1 |

18,6 |

39 000 |

- |

- |

|

2 |

31,5 |

16 200 |

- |

- |

|

3 |

43,5 |

9 600 |

69 751 526 |

108 530 977 |

|

4 |

55,4 |

25 200 |

20 819 006 |

36 682 590 |

|

5 |

67,3 |

0 |

- |

- |

|

6 |

79,2 |

1 800 |

4 025 542 |

6 142 909 |

|

7 |

91,2 |

3 600 |

2 636 425 |

3 706 939 |

|

8 |

103,1 |

7 200 |

1 824 836 |

2 565 807 |

|

9 |

115,0 |

8 600 |

1 314 941 |

1 848 870 |

|

10 |

127,0 |

7 800 |

976 312 |

1 372 741 |

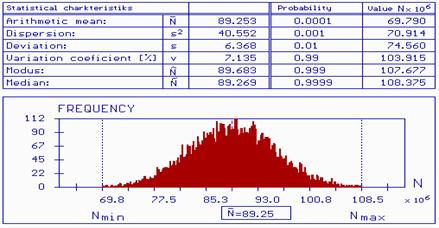

If the histograms of number of cycles to damage, which are adequate to stress levels in response spectrum are known, the formulation damage cumulation we can express in the form of vector

![]() (6)

(6)

For elected category of detail 100 above given S-N curve

for normal stress in table 1 for stress levels from stress range

spectrum are determined limits of number of cycles

![]() and

and

![]() by

equation (4).

by

equation (4).

Fig.

8 Histogram

![]()

![]() and

statistical characteristics of number of cycle to damage for stress

range level

and

statistical characteristics of number of cycle to damage for stress

range level

![]()

![]()

Minimal value

![]() is

expressed from curve considered detail category 100 and maximal value

is

expressed from curve considered detail category 100 and maximal value

![]() is

expressed from neighbor upper curve of category detail 112.

Considering that stress levels of blocks 1 and 2 are under threshold

values, they are not considered in computation of damage cumulation.

For upper stress range levels will prepare histograms

is

expressed from neighbor upper curve of category detail 112.

Considering that stress levels of blocks 1 and 2 are under threshold

values, they are not considered in computation of damage cumulation.

For upper stress range levels will prepare histograms

![]() .

After preparing of necessary characteristics we can write vector of

damage cumulation

.

After preparing of necessary characteristics we can write vector of

damage cumulation

![]() (7)

(7)

Where

![]() is

number of years of crane way exploitation.

is

number of years of crane way exploitation.

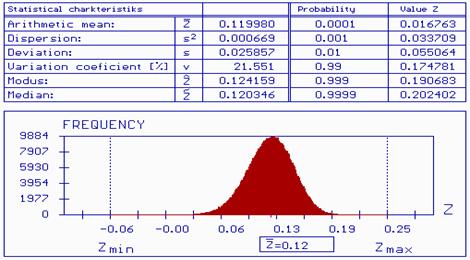

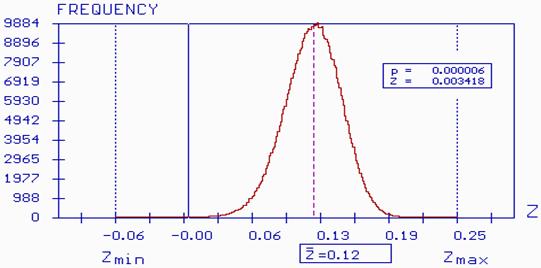

5. Reliability assessment

Fig.

9 Histogram and statistical characteristics of

reliability reserve

![]()

Fig.

10 Marking of probability failure in histogram of

reliability reserve

![]()

The reliability structure of crane way from the point of view of high cycle fatigue damage using probabilistic approach [1], [2], [3] [8] we can express function of reserve reliability

![]() (8)

(8)

Where

![]() is

limit value of damage accumulation, which is given of value 1.

is

limit value of damage accumulation, which is given of value 1.

Computation function of reliability reserve is made by M-Star program for 500000 simulation (see fig. 9).

Probability of failure

![]() is

calculated by using simulation method Monte Carlo for time of

exploitation

is

calculated by using simulation method Monte Carlo for time of

exploitation

![]() =

49,2 years

=

49,2 years

![]() =

0,000006 <

=

0,000006 <

![]() =

0,00007

(9)

=

0,00007

(9)

Where

![]() is

design value of probability failure by table A1 in STN 731401.

is

design value of probability failure by table A1 in STN 731401.

6. Conclusions

The application of reliability condition of high cycle fatigue belong to relative complicate tasks from the point of view on various random variable characteristics, which enter from side of loading effect expressed by stress range spectrum and also from the side of resistance of structure expressed by S-N curves. Probabilistic approach using Monte Carlo simulation was applied in the analysis of the load-effects spectrum and also the stress range spectrum using program called CRANE WAY, developed in cooperation with Prof. P. Marek within the framework of an earlier research project. Reliability analysis is based on the SBRA method [1] and M-Star program was used.

[1] MAREK, P. - GUŠTAR, M. and ANAGNOS, T.: Simulation-Based Reliability Assessment for Structural Engineers. CRC Press, New York, 1996.

[2] MAREK, P. - GUŠTAR, M. and BATHON, L.: Tragwerksbemessung von detrminstischen zu probabilistischen verfahren. ACADEMIA Praha, 1998.

[3] MAREK, P. - BROZZETI and GUŠTÁR, M.: Probabilistic Assessment of Structures using Monte Carlo simulation. Praha 2001.

[4] HUDÁK, J. - MAREK, P. - VIRČÍK, J.: Vybrané state z kovových konštrukcií a mostov. Únava a krehký lom oceľových dielcov. ES VŠT Košice, 1987.

[5] HUDÁK, J. - KUĽKOVÁ, E.: Meddling of real loading process and response determination by the simulation on a computer. In: Proceedings of the 2nd International Scientific Colloquium CAE TECHNIQUES. Bielefeld , 1995.

[6] HUDÁK, J.: Spektrá rozkmitov napätí nosníka žeriavovej dráhy pri posudzovaní na únavu. In.: Zborník „IV. Naukowa konferencja Rzeszowsko-Lwowska – Problemy budownictwa i inżinierii środowiska“, Rzeszów, 1995.

[7] HUDÁK, J.: K problematike posudzovania spoľahlivosti oceľových konštrukcií na únavu v STN 731401. Inžinierske stavby č. 7-8, Bratislava, 1997.

[8] VLK, M.: Využití simulační metody Monte Carlo při hodnocení životnosti v oblasti vysokocyklové únavy. In.: Conference ENGNEERING MECHANICS ´ 95, Svratka 1995.